Исследование свойств пленки из полиэфирэфиркетона (PEEK)

Полиэфирэфиркетон (PEEK) обладает свойствами устойчивости к высоким температурам, усталостной прочности, химической стойкости, износостойкости, устойчивости к гидролизу, а также превосходными механическими свойствами, барьерными свойствами, электрическими свойствами, радиационной стойкостью и т. д. Он привлек широкое внимание ученых из дома и за рубежом, были проведены углубленные исследования свойств и модификации материала. Он используется в машиностроении, нефтехимии, атомной энергетике, железнодорожном транспорте и биомедицинских материалах.

Пленка PEEK является важной формой PEEK, а также используется в качестве конструкционных пластиков и волокон. Областями его внутреннего применения являются в основном диафрагмы электронных изделий, слои теплоизоляционной пленки авиационных звукоизоляционных одеял, термостойкие изоляционные ленты и гибкие печатные платы. В настоящее время пленка PEEK в основном зависит от импорта, и лишь очень небольшое количество отечественных компаний добились промышленного производства пленки PEEK.

В данной статье готовится серия пленок PEEK методом экструзионного литья. Допуск по толщине приготовленных пленок небольшой, а плоскостность поверхности пленки высокая. Обсуждаются основные свойства, оптические свойства, механические свойства и факторы, влияющие на механические свойства пленок PEEK, а также предоставляются некоторые базовые данные. Есть надежда, что индустриализация пленок PEEK в Китае будет ускорена, а сфера применения пленок PEEK расширится.

Основные свойства пленки PEEK

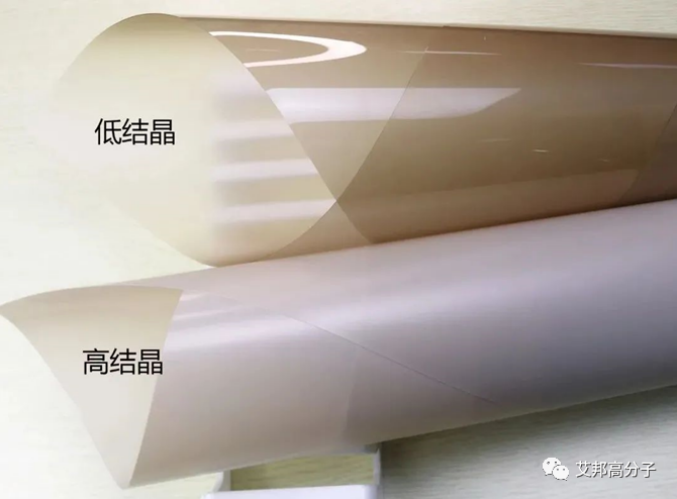

PEEK – полукристаллический полимер. Светопропускание и физические свойства пленки тесно связаны со структурной морфологией молекулярной цепи полимера. Пленка PEEK имеет непрозрачный коричневый цвет в состоянии высокой кристалличности и прозрачную светло-коричневую в состоянии от аморфной до низкой кристалличности. На рисунке ниже фото подготовленной пленки PEEK.

Фото пленки PEEK

The density of PEEK film is 1.26~1.30 g/cm3, the density in amorphous state is 1.26g/cm3, the glass transition temperature of PEEK film is 145℃, the cold crystallization peak temperature is 174℃, and the melting point is 341℃.

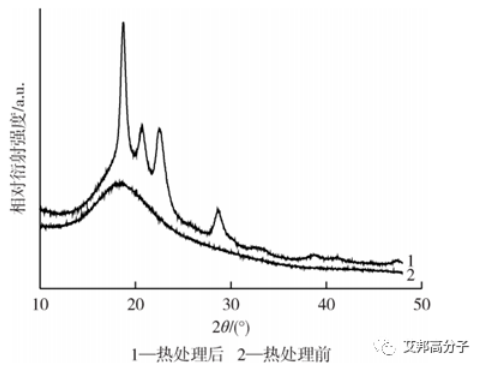

The PEEK film with a transmittance of 84.6% and a thickness of 95μm was heated at 250℃ for 20min for heat treatment. The figure below shows the wide-angle XRD spectra of the PEEK film before and after heat treatment. PEEK belongs to the orthorhombic crystal system. The crystallinity of the film before heat treatment is low. After heat treatment, the PEEK film has 4 main diffraction peaks, which appear at 18.7°, 20.6°, 22.6°, and 28.6°, respectively, corresponding to 110, 111, 200, 211, and 202 directions, respectively. The peaks in the 211 and 202 directions overlap. The test data is consistent with the literature reports. Since PEEK is a semi-crystalline polymer, the amorphous region causes a higher diffraction peak background.

Wide-angle XRD spectrum of PEEK film

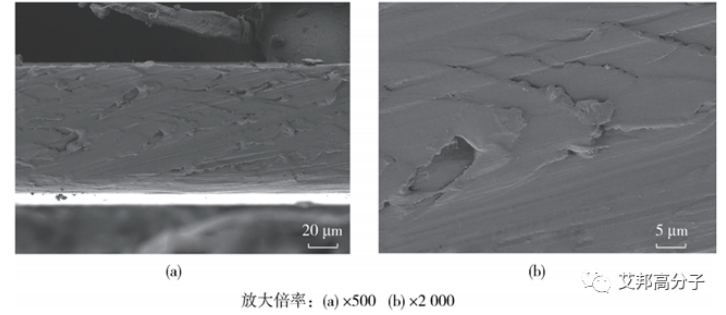

The figure below is a SEM photo of the cross-sectional structure of a PEEK film. The PEEK film can maintain high toughness in liquid nitrogen. The PEEK film prepared by the extrusion casting method has a casting roll temperature higher than the glass transition temperature of PEEK. Since the casting roll has a certain rotation speed, the film has a certain stretch in the longitudinal direction. From the figure, it can be observed that the longitudinal section of the film has a high degree of orientation of the polymer molecular chain along the stretching direction.

SEM photo of the cross section of PEEK film

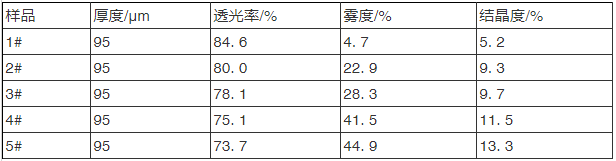

Relationship between film crystallinity and transmittance

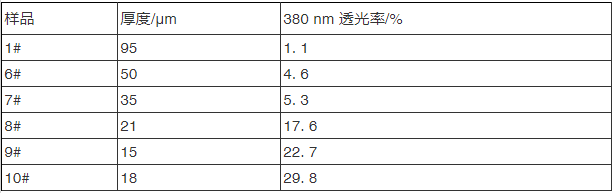

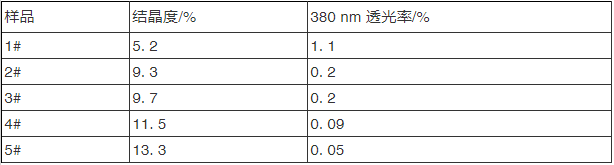

The temperature and speed of the casting roll directly affect the structure and thickness of the film. The relationship between transmittance and crystallinity is shown in Table 1. When the film thickness is the same, the higher the crystallinity, the lower the transmittance.

Table 1 Relationship between transmittance and crystallinity

The haze of the film can also reflect the color state of the film. The higher the crystallinity, the larger the haze value. When the crystallinity is below 5%, the film is highly transparent and clear.

PEEK film

Analysis of mechanical properties of cast film

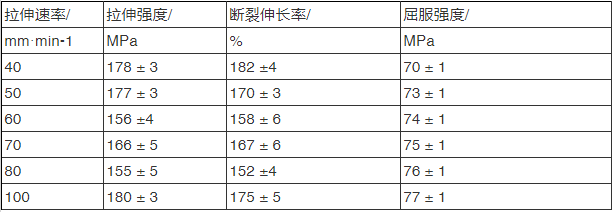

Since there is no standard for PEEK film in China, the methods for tensile testing of PEEK film in academic literature are not unified, and the influence of tensile rate on the mechanical properties of film needs to be explored. 18μm PEEK cast film was used for testing, and the tensile rate of the film was tested from 40 to 100 mm/min. The experimental results are shown in Table 2.

Table 2 Relationship between mechanical properties and tensile rate

The tensile strength of the samples showed a common point, that is, the tensile rate had little effect on the tensile strength and elongation at break. Increasing the tensile rate significantly increased the yield strength. When the tensile rate was 100 mm/min, the tensile strength of the film was still high. The mechanical properties of the PEEK film in this paper were tested at a tensile speed of 100 mm/min.

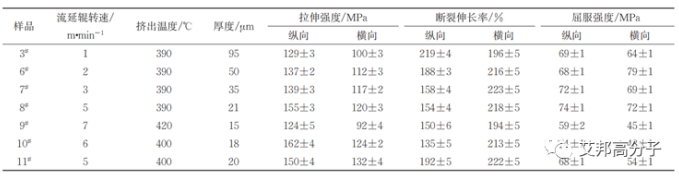

The effect of the casting roll speed on the mechanical properties is shown in Table 3. Under the same extruder temperature and screw speed, different casting roll speeds will lead to changes in film thickness. The higher the casting roll speed, the thinner the film. Therefore, the film has a certain stretch in the longitudinal direction. As the casting roll speed increases, the stretching becomes larger. From the longitudinal tensile strength data, the tensile strength increases with the increase of the casting roll speed, from 129 MPa of the 95μm film to 155 MPa. The elongation at break tends to decrease with the increase of the casting roll speed. Corresponding to the trend, the yield strength increases. From the transverse tensile data, the transverse tensile strength increases with the increase of the casting roll speed, but there is no obvious fixed trend in the elongation at break and the yield strength.

Table 3 Effects of casting roll speed and extrusion temperature on film mechanical properties

Table 3 Effects of casting roll speed and extrusion temperature on film mechanical properties

The extrusion temperature has an impact on the mechanical properties of the film. Due to the high processing temperature, side reactions such as partial degradation occur during the melt extrusion process. The melting point peak of PEEK is around 340°C. DSC data shows that it is completely melted at 350°C, so it can be processed at a processing temperature above 370°C. By comparing the mechanical properties at extrusion temperatures of 390, 400, and 420°C, the processing stability of the PEEK material is verified. As can be seen from Table 3, the mechanical properties of PEEK are stable at 390~400°C. Even if the temperature reaches 420°C, it can still maintain a high mechanical strength. PEEK has a wide processing temperature, which is conducive to production and processing.

Analysis of Mechanical Properties of Biaxially Stretch Films

PEEK film has a high elongation at break at room temperature, but the tensile strength of cast film is low, and its application in some fields may be limited. The key to controlling the thickness of cast film lies in the die head. The thickness tolerance of the film prepared by the cast method is large, and the biaxial stretching method will reduce the thickness tolerance of the film.

At the same time, the tensile strength of the film can be improved by biaxial stretching. Sample 1# was subjected to biaxial stretching test at 170°C with a stretching rate of 0.3 m/min. When the stretching ratio exceeded longitudinal × transverse = 2.5 × 2.5 times, the film was prone to rupture. Therefore, the stretching ratio was adjusted to longitudinal × transverse = 2 × 2 to study the effect of biaxial stretching on film performance.

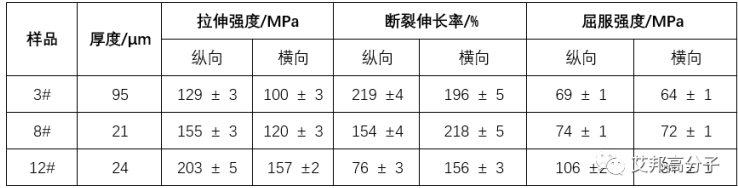

The mechanical properties of biaxially stretched film sample 12# were compared with those of sample 3# before stretching and sample 8# of equivalent thickness. It can be seen from Table 4 that biaxial stretching can greatly improve the mechanical properties of the film. The longitudinal tensile strength can reach 203MPa, but the elongation at break is reduced to 76%. The yield strength and elastic modulus of the film are also greatly improved, that is, the film has good rigidity.

Table 4 Mechanical properties of biaxially oriented PEEK films

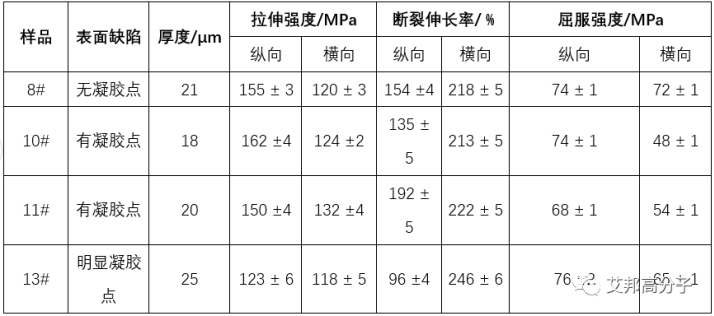

Analysis of surface defects and thin film mechanical properties

The experiment found that the die head is the key factor restricting the surface quality of the film. Incomplete cleaning of the screw and die head affects the surface of the PEEK film. After the extruder is shut down, it is difficult to clean the screw and die head with the PEEK raw material when it is restarted. There will be more char materials and gel points on the film, which will affect the surface quality and performance of the film. The film was tested after rinsing the PEEK raw material for 2 hours, and samples 10#, 11#, and 13# were obtained, and compared with sample 8#. The results are shown in Table 5. Gel points and char materials affect the surface quality of the film, but a small amount of gel points has little effect on the mechanical properties of the film.

Table 5 Effect of surface defects on the mechanical properties of films

Analysis of UV resistance of thin films

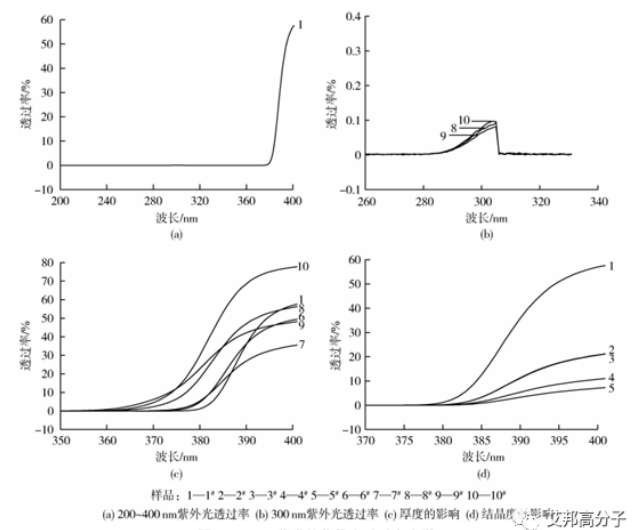

The PEEK film was tested by UV absorption spectrum, and the absorption spectrum could not be obtained because it exceeded the detection range. The UV transmission spectrum is shown in the figure.

UV transmittance spectrum of PEEK film

Figure (a) shows the UV transmission spectrum of a 95μm film in the range of 200~400 nm. It can be seen that the UV transmittance below 380 nm is 0, indicating that the PEEK film has anti-UV properties.

PEEK film has weak UV transmittance at 300nm. Figure 5(b) shows that the UV transmittance of the film with a thickness of 15~21μm is 0.1% at 300nm, while the UV transmittance of the film with a thickness of 95μm is 0.02% at 300nm. As the film thickness increases, the transmittance decreases.

На рис. 5(в) показаны УФ-спектры пропускания пленок ПЭЭК различной толщины в диапазоне 350-400 нм. В таблице 6 показана зависимость между коэффициентом пропускания УФ-излучения при 380 нм и толщиной пленки. Видно, что с увеличением толщины пленки коэффициент пропускания УФ-света при длине волны 360-380 нм уменьшается, а защита от УФ-излучения улучшается.

Таблица 6. Зависимость между коэффициентом пропускания УФ-излучения и толщиной пленки

Фиг.5(d) представляет собой УФ-спектры пропускания пленок PEEK одинаковой толщины и различной кристалличности. Как показано на фиг.5(d) и данных в таблице 7, существует небольшая разница в коэффициенте пропускания УФ-излучения при длине волны 380 нм. Когда кристалличность высока, защита от ультрафиолета лучше.

Таблица 7. Связь между коэффициентом пропускания УФ-излучения и кристалличностью

Вкратце, выводы следующие:

(1) Пропускание пленки PEEK уменьшается с увеличением кристалличности; скорость растяжения мало влияет на прочность на разрыв и удлинение при разрыве, а предел текучести значительно увеличивается с увеличением скорости растяжения; предел прочности увеличивается с увеличением скорости разливочного валка; механические свойства пленки PEEK стабильны при экструзии при температуре 390–400 ℃, и даже когда температура экструзии достигает 420 ℃, пленка PEEK все еще может сохранять высокую механическую прочность;

(2) Двухосное растяжение после отливки может значительно повысить прочность пленки PEEK на разрыв. Коэффициент растяжения составляет продольное × поперечное = 2 × 2. Прочность на растяжение в продольном направлении может достигать 203 МПа, а удлинение при разрыве — 76%. Поперечная прочность на разрыв составляет 157 МПа, удлинение при разрыве — 156%.

(3) Пленка PEEK обладает анти-ультрафиолетовыми свойствами. По мере увеличения толщины пленки кристалличность улучшается, коэффициент пропускания ультрафиолетового света при длине волны 360–380 нм уменьшается, а анти-ультрафиолетовые характеристики улучшаются.

(Статьи и картинки взяты из Интернета)